Catalytic gas-liquid reactions with the BUSS-Loop® Reactor, but not only…

BUSS ChemTech built up its reputation in process technology and reaction engineering with the BUSS-Loop® Reactor which was first sold in the 1950’s for the hydrogenation of fats and oils. Since then, we have continuously updated the system, enlarging the know-how to ancillary unit operations and processes.

Today we offer a wide range of services around a tailor-made industrial BUSS-Loop® Reactor, which can be designed for batch or semi-batch operation, or for continuous flow mode with an integrated inline filter system.

Unit operations for pre- and post-treatment, catalyst preparation and filtration, mixing or separation of solvents, separation of by-products from the reactor headspace, are challenges welcome and not unknown to our process and project engineers.

We can assist our clients with a wide variety of gas-liquid reaction chemistries. A few of them include, but are not limited to:

- Hydrogenations (bonds of all kinds)

- Alkoxylation

- Phosgenation

- Amination (including reductive)

- Alkylation (including reductive)

- Chlorination

- Oxidation

- and many others…

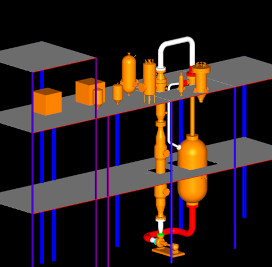

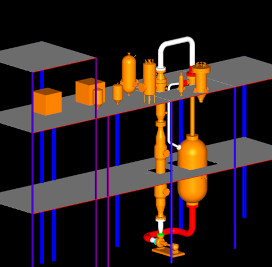

The Buss-Loop® Reactor

The unrivaled solution for high efficiency reaction engineering

BUSS-Loop® Explained

Continuous Operation

The Gas Circuit

Scaling up the BUSS-Loop®

Selected Applications of the BUSS-Loop® Reactor

Hydrocarbon Resins

Buss ChemTech is a leading technology supplier in the field of hydrocarbon resins, both base (HCR) and hydrogenated ones (HHCR).

Naturally, our technology is centred around the proven performance characteristics of the Buss Loop® Reactor, which achieves the highest mass transfer rates for the hydrogenation in comparison to other technologies. Our HCR technology allows clients to reduce solvent usage, minimize catalyst consumption and deliver consistently high quality water white resins. Our experience also includes partial and selective hydrogenations.

The distinctive feature of our hydrogenation technology is the continuous operation mode with a uniquely integrated catalyst filtration concept. Cutting edge solutions for polymerization are available on demand.

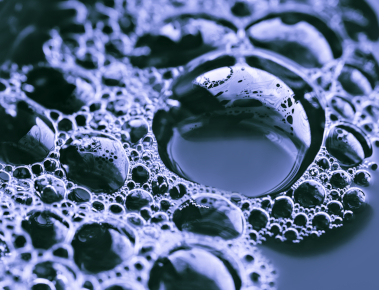

Surfactants

The global consumption of surfactants, for home and personal care or industrial applications, continually challenges reaction engineering towards high standards and innovation.

The versatility of the BUSS-Loop® across several chemistries, along with unique process development approach, made us a reference technology provider with decades of experience in ethoxylation for non-ionic surfactants, or partners to develop specific products like DMAPA.

Phosgene Chemistry

Built on 35 years of experience delivering technology and equipment for the safe and economical production of phosgene, Buss ChemTech can also provide the technology for downstream phosgenation reactions.

The Advanced Phosgenation Reactor sets new standards for safe and efficient production of phosgene derivatives.

Specialty Chemicals

Travelling through the chemistry is a fascinating adventure into markets, products, applications and people's life.

Regardless if you are a chemist, an engineer, or just a curious learner, you may spend hours in discussing the appropriate segmentation, upstream and downstream limits of the caleidoscopic family of the specialty chemicals, with only one fixed point: the Buss-Loop® Reactor will always accompany you.

Oleochemicals

Our competence in the oleochemicals market segment is rooted to the origin of the BUSS-Loop® Reactor, unrivalled till nowadays since the earliest applications in Latin America in the 1950's.

Millions of tons of Fatty Amines, Nitriles, Alcohols, Esters, have been manufatured woldwide with our technology and helped to make people's life better. Mastering the design of the gas circuit of the loop reactor is a key technology requisite leadership in its applications for the oleochemicals, the gas phase often having a crucial effect on equilibrium of the relevant reactions.

Polymer Modification

In every polymer and oligomer production process there is at least one essential step in the liquid solution or slurry phase.

The BUSS-Loop® Reactor can perform successfully for this step, even at moderate viscosities, in modification processes of the base macromolecule to functionalize it, to modify its features, or its performance.

Sugar Alcohols

For decades, BUSS-Loop® Reactor Technology has successfully been used for the production of sorbitol and other sugar alcohols.

Sorbitol and its derivatives are used as ingredients in toothpaste and cosmetics as well as in foods and beverages. Sorbitol is an intermediate in the synthesis of Vitamin C and also in the production of a wide range of industrial chemicals used to make resins, adhesives, and additives for processing textiles, metals, paper and leather.

Other important sugar alcohols include maltitol, xylitol and lactitol which are used primarily as food additives.

Buss Loop® Reactor Technology for sorbitol and other sugar alcohols is based on hydrogenation of the corresponding sugar with two differ-ent catalyst systems: ruthenium (Ru/C) or Raney-nickel as slurry-phase catalyst.

Numerous plants have been designed and constructed using BUSS ChemTech's process and Hydrogenation Technology for the production of Sorbitol, Xylitol, Lactitol, and other sugar alcohols.

Continuos hydrogenation process is available too, on demand.

Polycarboxylate Superplasticizers

In the construction industry, despite the introduction of many novel compounds, the traditional materials have been subject to continuous innovation and improvement.

In modern concrete, chemical admixtures continue to play a crucial role, with superplasticizers standing in the center of the technology. For polycarboxylate superplasticizers (PCEs) only, current global production volume far exceeds 10 million tons per year - even after more than 40 years from their invention.

They are essentially polyethylene glycol (PEG), which are produced starting from various molecules to which a polyether chain is added by ethoxylation, obtaining the desired “x-PEG”.

Since its breakthrough in Ethylene Oxide Derivatives with the alkoxylation process performed using the BUSS-Loop® Reactor, BUSS ChemTech accompanied industry leaders and new producers in their effort to serve the market with innovation and high standards.

CO2 Chemistry

Our planet’s journey is a challenge to scientists, chemists, engineers and everyone trying to find sustainable solutions.

One target, among others, is the reduction of CO₂. This can be done by reducing emissions but also by capture and re-use of the remaining emissions ones.

Buss ChemTech participates in this collective effort and has already made its technology available for successful development.

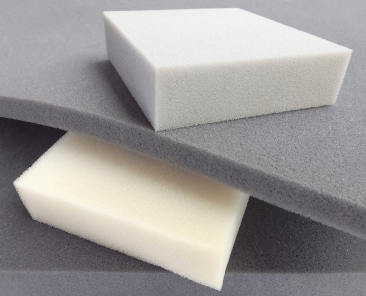

Polyurethane Chemistry

Polyurethanes are among most versatile polymeric materials, moldable in different forms and shapes that are found in various industrial and consumer products.

Polyurethanes are formed by reacting a polyol (an alcohol with more than two reactive hydroxyl groups per molecule) with a diisocyanate or a polymeric isocyanate in the presence of suitable catalysts and additives.

The variety of diisocyanates and of polyols is wide and leads to many formulations and applications, so that polyurethanes can be found in mattresses, couches, insulation, liquid coatings and paints, soft flexible foam toys, tough elastomers such as roller blade wheels, some elastic fibers, and many other products.

Diving into the building blocks that make polyurethanes, once again the versatility of BUSS ChemTech technology can play a role, both on the Isocyanates and Polyols side.

Aniline and Toluenediamine (TDA) are the precursors of methylene diphenyl diisocyanate (MDI) and toluene diisocyanate (TDI) respectively, and can be respectively obatined by hydrogenating in the BUSS-Loop® Reactor nitrobenzene (NB) and dinitrobenzene (DNB).

Selected Applications of the BUSS-Loop® Reactor

Hydrocarbon Resins

Buss ChemTech is a leading technology supplier in the field of hydrocarbon resins, both base (HCR) and hydrogenated ones (HHCR).

Naturally, our technology is centred around the proven performance characteristics of the Buss Loop® Reactor, which achieves the highest mass transfer rates for the hydrogenation in comparison to other technologies. Our HCR technology allows clients to reduce solvent usage, minimize catalyst consumption and deliver consistently high quality water white resins. Our experience also includes partial and selective hydrogenations.

The distinctive feature of our hydrogenation technology is the continuous operation mode with a uniquely integrated catalyst filtration concept. Cutting edge solutions for polymerization are available on demand.

Surfactants

The global consumption of surfactants, for home and personal care or industrial applications, continually challenges reaction engineering towards high standards and innovation.

The versatility of the BUSS-Loop® across several chemistries, along with unique process development approach, made us a reference technology provider with decades of experience in ethoxylation for non-ionic surfactants, or partners to develop specific products like DMAPA.

Phosgene Chemistry

Built on 35 years of experience delivering technology and equipment for the safe and economical production of phosgene, Buss ChemTech can also provide the technology for downstream phosgenation reactions.

The Advanced Phosgenation Reactor sets new standards for safe and efficient production of phosgene derivatives.

Specialty Chemicals

Travelling through the chemistry is a fascinating adventure into markets, products, applications and people's life.

Regardless if you are a chemist, an engineer, or just a curious learner, you may spend hours in discussing the appropriate segmentation, upstream and downstream limits of the caleidoscopic family of the specialty chemicals, with only one fixed point: the Buss-Loop® Reactor will always accompany you.

Oleochemicals

Our competence in the oleochemicals market segment is rooted to the origin of the BUSS-Loop® Reactor, unrivalled till nowadays since the earliest applications in Latin America in the 1950's.

Millions of tons of Fatty Amines, Nitriles, Alcohols, Esters, have been manufatured woldwide with our technology and helped to make people's life better. Mastering the design of the gas circuit of the loop reactor is a key technology requisite leadership in its applications for the oleochemicals, the gas phase often having a crucial effect on equilibrium of the relevant reactions.

Polymer Modification

In every polymer and oligomer production process there is at least one essential step in the liquid solution or slurry phase.

The BUSS-Loop® Reactor can perform successfully for this step, even at moderate viscosities, in modification processes of the base macromolecule to functionalize it, to modify its features, or its performance.

Sugar Alcohols

For decades, BUSS-Loop® Reactor Technology has successfully been used for the production of sorbitol and other sugar alcohols.

Sorbitol and its derivatives are used as ingredients in toothpaste and cosmetics as well as in foods and beverages. Sorbitol is an intermediate in the synthesis of Vitamin C and also in the production of a wide range of industrial chemicals used to make resins, adhesives, and additives for processing textiles, metals, paper and leather.

Other important sugar alcohols include maltitol, xylitol and lactitol which are used primarily as food additives.

Buss Loop® Reactor Technology for sorbitol and other sugar alcohols is based on hydrogenation of the corresponding sugar with two differ-ent catalyst systems: ruthenium (Ru/C) or Raney-nickel as slurry-phase catalyst.

Numerous plants have been designed and constructed using BUSS ChemTech's process and Hydrogenation Technology for the production of Sorbitol, Xylitol, Lactitol, and other sugar alcohols. Continuos hydrogenation process is available too, on demand.

Polycarboxylate Superplasticizers

In the construction industry, despite the introduction of many novel compounds, the traditional materials have been subject to continuous innovation and improvement.

In modern concrete, chemical admixtures continue to play a crucial role, with superplasticizers standing in the center of the technology. For polycarboxylate superplasticizers (PCEs) only, current global production volume far exceeds 10 million tons per year - even after more than 40 years from their invention.

They are essentially polyethylene glycol (PEG), which are produced starting from various molecules to which a polyether chain is added by ethoxylation, obtaining the desired “x-PEG”.

Since its breakthrough in Ethylene Oxide Derivatives with the alkoxylation process performed using the BUSS-Loop® Reactor, BUSS ChemTech accompanied industry leaders and new producers in their effort to serve the market with innovation and high standards.

CO2 Chemistry

Our planet’s journey is a challenge to scientists, chemists, engineers and everyone trying to find sustainable solutions.

One target, among others, is the reduction of CO₂. This can be done by reducing emissions but also by capture and re-use of the remaining emissions ones.

Polyurethane Chemistry

Polyurethanes are among most versatile polymeric materials, moldable in different forms and shapes that are found in various industrial and consumer products.

Polyurethanes are formed by reacting a polyol (an alcohol with more than two reactive hydroxyl groups per molecule) with a diisocyanate or a polymeric isocyanate in the presence of suitable catalysts and additives.

The variety of diisocyanates and of polyols is wide and leads to many formulations and applications, so that polyurethanes can be found in mattresses, couches, insulation, liquid coatings and paints, soft flexible foam toys, tough elastomers such as roller blade wheels, some elastic fibers, and many other products.

Diving into the building blocks that make polyurethanes, once again the versatility of BUSS ChemTech technology can play a role, both on the Isocyanates and Polyols side.

Aniline and Toluenediamine (TDA) are the precursors of methylene diphenyl diisocyanate (MDI) and toluene diisocyanate (TDI) respectively, and can be respectively obatined by hydrogenating in the BUSS-Loop® Reactor nitrobenzene (NB) and dinitrobenzene (DNB).

Success Stories

BUSS ChemTech delivers first integrated HCR/HHCR plant

Based only on lab-scale tests to characterize the client’s raw material, we delivered a Technology Package for an integrated polymerization and hydrogenation plant to produce base and water white hydrocarbon resins.

Learn More

Development of a continuous SBS hydrogenation process

Demonstration of feasibility, first on a lab-scale (batch), then on the pilot-scale (continuous). Subsequent contract for the industrial plant.

Learn More

Upgrade of a BUSS-Loop® Reactor copy

Conversion of an existing hydrogenated hydrocarbon resin (HHCR) from batch to continuous operation.

Learn More

Client builds 2nd, larger plant based on BUSS-Loop® Reactor Technology

Supply of technology, engineering package and erection supervision for a batch alkylation plant.

Learn More

Customer replaces BUSS-Loop® Reactor…after 40 years of operation!

Supply of technology, engineering and equipment as well as erection supervision to the client

Learn MoreContact Us

* Required fields

Your Contact

Gianluca Premoli

Business Manager Reaction Technology

Other Topics of Interest

Our Development Capabilities

Every plant comes with guarantees. The basis of the guarantees, as well as the process design itself, is developed in our own extensive technical center.

Fact Sheet: Gas Liquid Reactions

The heart of our gas-liquid reaction process designs is the technology we invented in the late 1940’s and that we have been improving on ever since.

Scope of Project Delivery

From technology packages to modular and turnkey solutions, click below to find out about our range of services.