Molecule of the Month July 2019

N,N-Dimethylaminopropylamine (DMAPA)

Molecule of the Month

Date: July 2019

Subject: N,N-Dimethylaminopropylamine (DMAPA)

Dimethylaminopropylamine (DMAPA) is a clear, almost colourless liquid with a characteristic, amine-like odour. It has a boiling point of 135 °C and is soluble in water, benzene and many other organic solvents.

DMAPA is an important intermediate for the production of betains, which find a use as co-tensides for body care products like shampoo and washing lotion and as dishwashing detergents. Because of the increasing consumption of personal care products in the growing middle class of many countries an increasing market demand for DMAPA can be expected in the coming years.

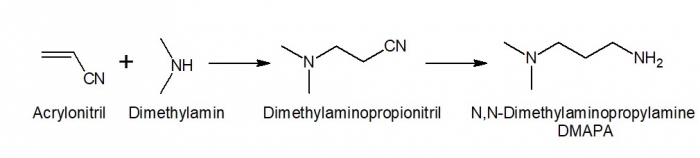

DMAPA is commonly produced commercially in two steps via the reaction of dimethylamine (DMA) with acrylonitrile (cyanoethylation) to dimethylaminopropionitrile followed by the catalytic hydrogenation of the nitrile to yield the product DMAPA.

BUSS ChemTech has developed an efficient process to produce DMAPA from dimethylamine and acrylonitrile based on BUSS Loop® Reactor technology, which is applied in both reaction steps.

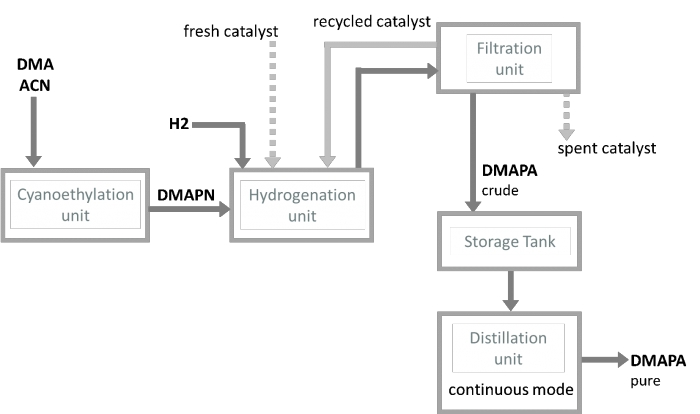

Block diagram for the DMAPA production process:

The cyanoethylation proceeds in the first BUSS Loop® Reactor by charging DMA and a small amount of water, which is known to accelerate the nucleophilic addition reaction. Acrylonitril is then added constantly while the temperature of the exothermic reaction is kept at 65 °C. The efficient mixing and the accurate temperature control characteristics of the loop reactor lead to complete conversion of acrylonitril and very high selectivity (> 99.9%) to the intermediate dimethylaminopropionitrile.

The hydrogenation unit utilizes our advanced loop reactor design, comprising a mixer/reaction pump combination optimized for enhanced gas load. The exothermic hydrogenation of the nitrile is carried out batchwise over Raney-Nickel and in the presence of ammonia to suppress the formation of secondary and tertiary amines. After filtration the crude DMAPA is purified in a continuous distillation unit to a final purity of greater than 99.5 wt%.

To learn more about our process technology, contact Thomas Blocher, Business Manager Reaction Technology at +41 61 825 6317 or by liam-e