Dynamic phosgene generation: the safe way to production.

Phosgene is a very versatile raw material commonly used in the production of many organic compounds. Reactions using phosgene produce high purity products with high yields. However, phosgene’s reactivity and toxicity make it a particular hazard and as such, regulatory authorities impose stringent safeguards on its storage, transportation and use. Alternative reagents, like thionylchloride or phosphorylchloride, however, pose even greater risks.

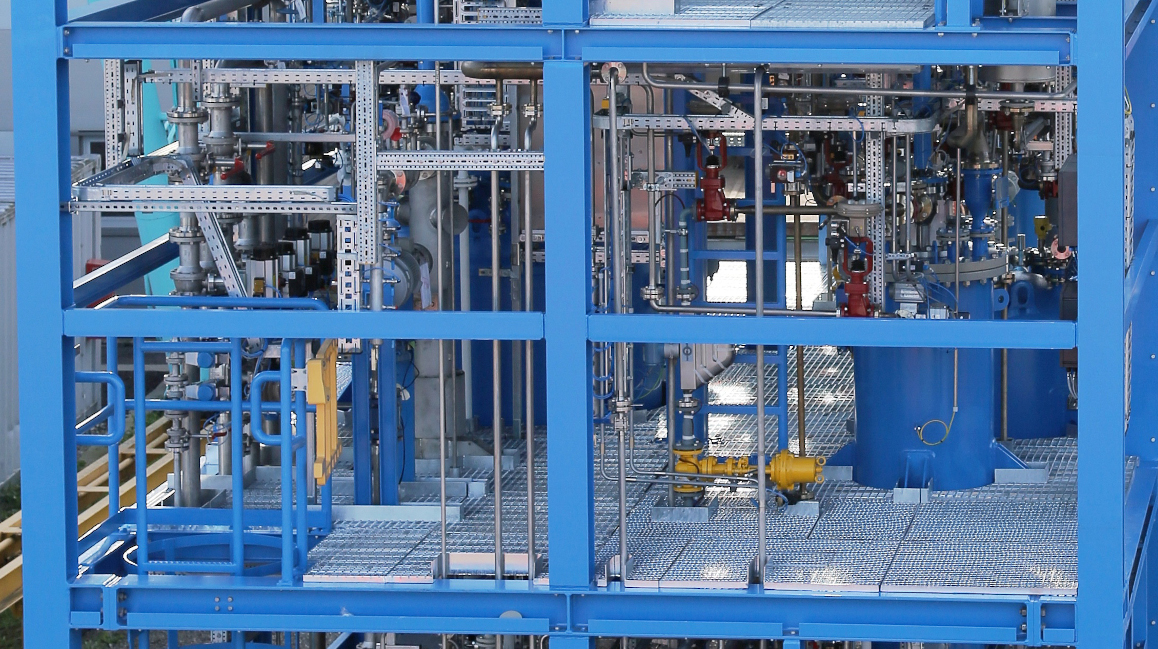

BUSS ChemTech has developed a unique system for the dynamic production of phosgene that avoids the liquefaction or storage of phosgene and incorporates features that safeguard the health and well-being of personnel and environment.

Over 30 years experience with phosgene

The BUSS ChemTech Phosgene Generator

From small modular units for specialty products to large stick-built plants for commodities, we have a phosgene generator the right size for your needs.

Our Phosgene Safety Concept

«Safety» is not a buzz word at BUSS ChemTech but rather the first criteria we consider at every stage of process and plant design.

Reliability is second only to safety

Downstream reactions can be batch or continuous, which requires a plant that can realiably produce phosgene when it is needed, day in, day out.

Success Stories

Skid Mounted Phosgene Unit

BUSS ChemTech to deliver a second phosgene production unit to India.

Learn MoreContact Us

* Required fields

Your Contact

Gianluca Premoli

Business Manager Reaction Technology

Other Topics of Interest

Gas-Phase Reactions with Phosgene

The Advanced Phosgenation Reactor, based on the BUSS-Loop® Reactor, is the most efficienct gas-phase phosgenation reactor in the industry.

Fact Sheet:

Phosgene Generators

Like to learn more about our generators and our technology for reactions with phosgene? Then click on the link below.

Our Development Capabilities

Every plant comes with guarantees. The basis of the guarantees, as well as the process design itself, is developed in our own extensive technical center.