Katalytische Gas/Flüssig-Reaktionen mit dem BUSS-Loop® Reaktor, aber nicht nur…

Die BUSS ChemTech hat sich mit dem BUSS-Loop® Reaktor, der erstmals in den 1950er Jahren für die Hydrierung von Fetten und Ölen verkauft wurde, einen Namen in der Verfahrens- und Reaktionstechnik gemacht. Seitdem haben wir das System fortlaufend auf den neuesten Stand gebracht und das Know-how auf den Betrieb und die Prozesse von Nebenaggregaten ausgeweitet.

Heute bieten wir eine breite Palette von Dienstleistungen rund um einen massgeschneiderten industriellen BUSS-Loop® Reaktor, der für den Batch-, Halb-Batch- oder für den kontinuierlichen Durchflussbetrieb mit einem integrierten Inline-Filter-System ausgelegt werden kann.

Der Betrieb von Einheiten zur Vor- und Nachbehandlung, zur Katalysatoraufbereitung und ‑filtration, zur Mischung oder Abtrennung von Lösungsmitteln und zur Abtrennung von Nebenprodukten aus den Brüden sind willkommene Herausforderungen, die unsere Verfahrens- und Projektingenieure mit viel Erfahrung meistern.

Wir können unsere Kunden bei einer Vielzahl von Gas/Flüssig-Reaktionen unterstützen. Darunter:

- Hydrierungen (von Bindungen aller Art)

- Alkoxylierung

- Phosgenierung

- Aminierung

- Alkylierung

- Chlorierung

- Oxidation

- und viele andere…

Der Buss-Loop® Reaktor

Die unübertroffene Lösung für hocheffiziente Reaktionstechnik

BUSS-Loop® erklärt

Kontinuierlicher Betrieb

Der Gaskreislauf

Scale-up des BUSS-Loop®

Ausgewählte Anwendungen des BUSS-Loop® Reaktors

Hydrocarbon Resins

Buss ChemTech is a leading technology supplier in the field of hydrocarbon resins, both base (HCR) and hydrogenated ones (HHCR).

Naturally, our technology is centred around the proven performance characteristics of the Buss Loop® Reactor, which achieves the highest mass transfer rates for the hydrogenation in comparison to other technologies. Our HCR technology allows clients to reduce solvent usage, minimize catalyst consumption and deliver consistently high quality water white resins. Our experience also includes partial and selective hydrogenations.

The distinctive feature of our hydrogenation technology is the continuous operation mode with a uniquely integrated catalyst filtration concept. Cutting edge solutions for polymerization are available on demand.

Surfactants

The global consumption of surfactants, for home and personal care or industrial applications, continually challenges reaction engineering towards high standards and innovation.

The versatility of the BUSS-Loop® across several chemistries, along with unique process development approach, made us a reference technology provider with decades of experience in ethoxylation for non-ionic surfactants, or partners to develop specific products like DMAPA.

Phosgene Chemistry

Built on 35 years of experience delivering technology and equipment for the safe and economical production of phosgene, Buss ChemTech can also provide the technology for downstream phosgenation reactions.

The Advanced Phosgenation Reactor sets new standards for safe and efficient production of phosgene derivatives.

Specialty Chemicals

Travelling through the chemistry is a fascinating adventure into markets, products, applications and people's life.

Regardless if you are a chemist, an engineer, or just a curious learner, you may spend hours in discussing the appropriate segmentation, upstream and downstream limits of the caleidoscopic family of the specialty chemicals, with only one fixed point: the Buss-Loop® Reactor will always accompany you.

Oleochemicals

Our competence in the oleochemicals market segment is rooted to the origin of the BUSS-Loop® Reactor, unrivalled till nowadays since the earliest applications in Latin America in the 1950's.

Millions of tons of Fatty Amines, Nitriles, Alcohols, Esters, have been manufatured woldwide with our technology and helped to make people's life better. Mastering the design of the gas circuit of the loop reactor is a key technology requisite leadership in its applications for the oleochemicals, the gas phase often having a crucial effect on equilibrium of the relevant reactions.

Polymer Modification

In every polymer and oligomer production process there is at least one essential step in the liquid solution or slurry phase.

The BUSS-Loop® Reactor can perform successfully for this step, even at moderate viscosities, in modification processes of the base macromolecule to functionalize it, to modify its features, or its performance.

Sugar Alcohols

For decades, BUSS-Loop® Reactor Technology has successfully been used for the production of sorbitol and other sugar alcohols.

Sorbitol and its derivatives are used as ingredients in toothpaste and cosmetics as well as in foods and beverages. Sorbitol is an intermediate in the synthesis of Vitamin C and also in the production of a wide range of industrial chemicals used to make resins, adhesives, and additives for processing textiles, metals, paper and leather.

Other important sugar alcohols include maltitol, xylitol and lactitol which are used primarily as food additives.

Buss Loop® Reactor Technology for sorbitol and other sugar alcohols is based on hydrogenation of the corresponding sugar with two differ-ent catalyst systems: ruthenium (Ru/C) or Raney-nickel as slurry-phase catalyst.

Numerous plants have been designed and constructed using BUSS ChemTech's process and Hydrogenation Technology for the production of Sorbitol, Xylitol, Lactitol, and other sugar alcohols.

Continuos hydrogenation process is available too, on demand.

Polycarboxylate Superplasticizers

In the construction industry, despite the introduction of many novel compounds, the traditional materials have been subject to continuous innovation and improvement.

In modern concrete, chemical admixtures continue to play a crucial role, with superplasticizers standing in the center of the technology. For polycarboxylate superplasticizers (PCEs) only, current global production volume far exceeds 10 million tons per year - even after more than 40 years from their invention.

They are essentially polyethylene glycol (PEG), which are produced starting from various molecules to which a polyether chain is added by ethoxylation, obtaining the desired “x-PEG”.

Since its breakthrough in Ethylene Oxide Derivatives with the alkoxylation process performed using the BUSS-Loop® Reactor, BUSS ChemTech accompanied industry leaders and new producers in their effort to serve the market with innovation and high standards.

CO2 Chemistry

Our planet’s journey is a challenge to scientists, chemists, engineers and everyone trying to find sustainable solutions.

One target, among others, is the reduction of CO₂. This can be done by reducing emissions but also by capture and re-use of the remaining emissions ones.

Buss ChemTech participates in this collective effort and has already made its technology available for successful development.

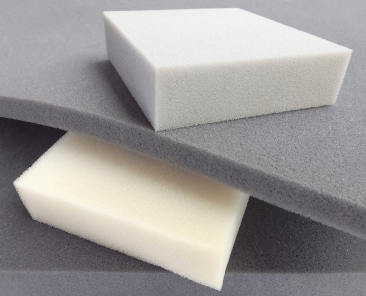

Polyurethane Chemistry

Polyurethanes are among most versatile polymeric materials, moldable in different forms and shapes that are found in various industrial and consumer products.

Polyurethanes are formed by reacting a polyol (an alcohol with more than two reactive hydroxyl groups per molecule) with a diisocyanate or a polymeric isocyanate in the presence of suitable catalysts and additives.

The variety of diisocyanates and of polyols is wide and leads to many formulations and applications, so that polyurethanes can be found in mattresses, couches, insulation, liquid coatings and paints, soft flexible foam toys, tough elastomers such as roller blade wheels, some elastic fibers, and many other products.

Diving into the building blocks that make polyurethanes, once again the versatility of BUSS ChemTech technology can play a role, both on the Isocyanates and Polyols side.

Aniline and Toluenediamine (TDA) are the precursors of methylene diphenyl diisocyanate (MDI) and toluene diisocyanate (TDI) respectively, and can be respectively obatined by hydrogenating in the BUSS-Loop® Reactor nitrobenzene (NB) and dinitrobenzene (DNB).

Ausgewählte Anwendungen des BUSS-Loop® Reaktors

Hydrocarbon Resins

Buss ChemTech is a leading technology supplier in the field of hydrocarbon resins, both base (HCR) and hydrogenated ones (HHCR).

Naturally, our technology is centred around the proven performance characteristics of the Buss Loop® Reactor, which achieves the highest mass transfer rates for the hydrogenation in comparison to other technologies. Our HCR technology allows clients to reduce solvent usage, minimize catalyst consumption and deliver consistently high quality water white resins. Our experience also includes partial and selective hydrogenations.

The distinctive feature of our hydrogenation technology is the continuous operation mode with a uniquely integrated catalyst filtration concept. Cutting edge solutions for polymerization are available on demand.

Surfactants

The global consumption of surfactants, for home and personal care or industrial applications, continually challenges reaction engineering towards high standards and innovation.

The versatility of the BUSS-Loop® across several chemistries, along with unique process development approach, made us a reference technology provider with decades of experience in ethoxylation for non-ionic surfactants, or partners to develop specific products like DMAPA.

Phosgene Chemistry

Built on 35 years of experience delivering technology and equipment for the safe and economical production of phosgene, Buss ChemTech can also provide the technology for downstream phosgenation reactions.

The Advanced Phosgenation Reactor sets new standards for safe and efficient production of phosgene derivatives.

Specialty Chemicals

Travelling through the chemistry is a fascinating adventure into markets, products, applications and people's life.

Regardless if you are a chemist, an engineer, or just a curious learner, you may spend hours in discussing the appropriate segmentation, upstream and downstream limits of the caleidoscopic family of the specialty chemicals, with only one fixed point: the Buss-Loop® Reactor will always accompany you.

Oleochemicals

Our competence in the oleochemicals market segment is rooted to the origin of the BUSS-Loop® Reactor, unrivalled till nowadays since the earliest applications in Latin America in the 1950's.

Millions of tons of Fatty Amines, Nitriles, Alcohols, Esters, have been manufatured woldwide with our technology and helped to make people's life better. Mastering the design of the gas circuit of the loop reactor is a key technology requisite leadership in its applications for the oleochemicals, the gas phase often having a crucial effect on equilibrium of the relevant reactions.

Polymer Modification

In every polymer and oligomer production process there is at least one essential step in the liquid solution or slurry phase.

The BUSS-Loop® Reactor can perform successfully for this step, even at moderate viscosities, in modification processes of the base macromolecule to functionalize it, to modify its features, or its performance.

Sugar Alcohols

For decades, BUSS-Loop® Reactor Technology has successfully been used for the production of sorbitol and other sugar alcohols.

Sorbitol and its derivatives are used as ingredients in toothpaste and cosmetics as well as in foods and beverages. Sorbitol is an intermediate in the synthesis of Vitamin C and also in the production of a wide range of industrial chemicals used to make resins, adhesives, and additives for processing textiles, metals, paper and leather.

Other important sugar alcohols include maltitol, xylitol and lactitol which are used primarily as food additives.

Buss Loop® Reactor Technology for sorbitol and other sugar alcohols is based on hydrogenation of the corresponding sugar with two differ-ent catalyst systems: ruthenium (Ru/C) or Raney-nickel as slurry-phase catalyst.

Numerous plants have been designed and constructed using BUSS ChemTech's process and Hydrogenation Technology for the production of Sorbitol, Xylitol, Lactitol, and other sugar alcohols. Continuos hydrogenation process is available too, on demand.

Polycarboxylate Superplasticizers

In the construction industry, despite the introduction of many novel compounds, the traditional materials have been subject to continuous innovation and improvement.

In modern concrete, chemical admixtures continue to play a crucial role, with superplasticizers standing in the center of the technology. For polycarboxylate superplasticizers (PCEs) only, current global production volume far exceeds 10 million tons per year - even after more than 40 years from their invention.

They are essentially polyethylene glycol (PEG), which are produced starting from various molecules to which a polyether chain is added by ethoxylation, obtaining the desired “x-PEG”.

Since its breakthrough in Ethylene Oxide Derivatives with the alkoxylation process performed using the BUSS-Loop® Reactor, BUSS ChemTech accompanied industry leaders and new producers in their effort to serve the market with innovation and high standards.

CO2 Chemistry

Our planet’s journey is a challenge to scientists, chemists, engineers and everyone trying to find sustainable solutions.

One target, among others, is the reduction of CO₂. This can be done by reducing emissions but also by capture and re-use of the remaining emissions ones.

Polyurethane Chemistry

Polyurethanes are among most versatile polymeric materials, moldable in different forms and shapes that are found in various industrial and consumer products.

Polyurethanes are formed by reacting a polyol (an alcohol with more than two reactive hydroxyl groups per molecule) with a diisocyanate or a polymeric isocyanate in the presence of suitable catalysts and additives.

The variety of diisocyanates and of polyols is wide and leads to many formulations and applications, so that polyurethanes can be found in mattresses, couches, insulation, liquid coatings and paints, soft flexible foam toys, tough elastomers such as roller blade wheels, some elastic fibers, and many other products.

Diving into the building blocks that make polyurethanes, once again the versatility of BUSS ChemTech technology can play a role, both on the Isocyanates and Polyols side.

Aniline and Toluenediamine (TDA) are the precursors of methylene diphenyl diisocyanate (MDI) and toluene diisocyanate (TDI) respectively, and can be respectively obatined by hydrogenating in the BUSS-Loop® Reactor nitrobenzene (NB) and dinitrobenzene (DNB).

Erfolgsgeschichten

Keine Ergebnisse gefunden

Die angefragte Seite konnte nicht gefunden werden. Verfeinern Sie Ihre Suche oder verwenden Sie die Navigation oben, um den Beitrag zu finden.

Kontakt

* Erforderliche Felder

Ihr Kontakt

Gianluca Premoli

Business Manager Reaction Technology

Andere Themen

Unsere Entwicklungskompetenzen

Jede Anlage wird mit Garantien geliefert. Die Grundlage der Garantien sowie das Prozessdesign selbst werden in unserem eigenen umfangreichen technischen Zentrum entwickelt.

Merkblatt: Gas/Flüssig-Reaktionen

Das Herzstück unserer Gas-Flüssig-Reaktionsverfahren ist die Technologie, die wir in den späten 1940er Jahren erfunden haben und die wir seitdem ständig verbessert haben.

Umfang der Projektlieferung

Von Technologiepaketen bis hin zu modularen und schlüsselfertigen Lösungen – klicken Sie unten, um sich über unser Dienstleistungsangebot zu informieren.