Chemical.

Process.

Engineering.

Technology & Plants

Guaranteed Swiss Quality –

Worldwide!

NEXTCHEM (Maire) to acquire BUSS ChemTech AG

The shareholders of Ballestra Group, BUSS ChemTech’s parent company, have agreed to sell 100% of the group to NEXTCHEM, Maire’s Sustainable Technology Solutions group. More information can be found by clicking on the link below.

Heritage in the

chemical industry:

140 years

Team dedicated

to Projects:

>60 personnel

Successful

installations:

>400

Installations

worldwide:

63 countries

Technologies

Gas-liquid Reactions

Phosgene Production

Fluorine Chemistry

Chemical Recycling

Success Stories

Selected projects from

our 140 years heritage

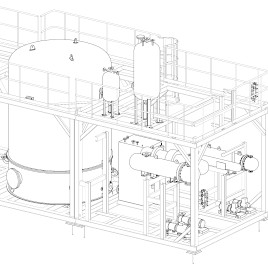

Skid Mounted Phosgene Unit

BUSS ChemTech to deliver a second phosgene production unit to India.

Learn More

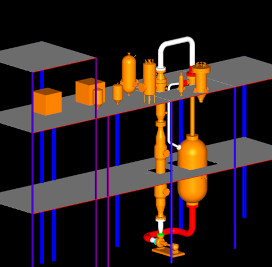

BUSS ChemTech delivers first integrated HCR/HHCR plant

Based only on lab-scale tests to characterize the client’s raw material, we delivered a Technology Package for an integrated polymerization and hydrogenation plant to produce base and water white hydrocarbon resins.

Learn More

Development of a continuous SBS hydrogenation process

Demonstration of feasibility, first on a lab-scale (batch), then on the pilot-scale (continuous). Subsequent contract for the industrial plant.

Learn More

Upgrade of a BUSS-Loop® Reactor copy

Conversion of an existing hydrogenated hydrocarbon resin (HHCR) from batch to continuous operation.

Learn More

A New Barrel Housing for a BUSS Kneader

Design, construction, on-site delivery, installation and start-up of a BUSS Kneader with a new barrel housing.

Learn More

Client builds 2nd, larger plant based on BUSS-Loop® Reactor Technology

Supply of technology, engineering package and erection supervision for a batch alkylation plant.

Learn More

Customer replaces BUSS-Loop® Reactor…after 40 years of operation!

Supply of technology, engineering and equipment as well as erection supervision to the client

Learn MoreOpen Positions

Project Engineer

Full-time, Pratteln

We are looking for an ambitious personality who enjoys working in a multi-discplinary, multi-cultural environment to reach out for the position of Project Engineer.