CO2 Chemistry

CO2 Mineralization

Carbon dioxide (CO2) can react with certain minerals, and by so doing, CO2 gets removed from the atmosphere and permanently stored in the mineral substrate.

Although the carbon mineralization process occurs naturally over hundreds or even thousands of years, it can accelerated by means of an appropriate reaction technology under specific conditions. The BUSS-Loop® Reactor, by its ability to handle multiphase slurry reactions, has demonstrated to be a valuable tool to support this process.

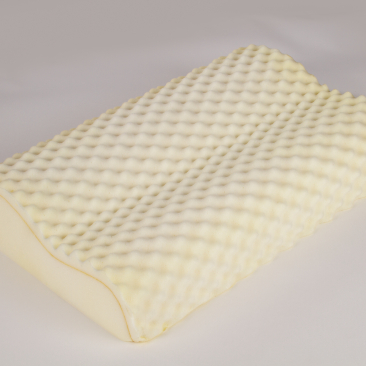

CO2-based Polyols

Abundant, inexpensive, renewable, and nontoxic, Carbon Dioxide (CO2) has become an attractive feedstock for chemical and polymer syntheses.

The use of CO2 as a sustainable precursor for polyurethane has become prominent in polymer industry, since the possibility to use CO2 in polyether polyols has been proven successfully.

The BUSS-Loop® Reactor, used for over three decades for non-ionic surfactant and polyol production, was used sucessfully for the production of CO2-based polyols, being able to handle simultanously the reaction of the chain starter with propylene oxide and carbon dioxide.

Contact Us

* Required fields

Your Contact

Gianluca Premoli

Business Manager Reaction Technology

Other Topics of Interest

Our Development Capabilities

Every plant comes with guarantees. The basis of the guarantees, as well as the process design itself, is developed in our own extensive technical center.

Fact Sheet:

Gas-liquid Reactions

Click below to download our Gas-Liquid Reactions Fact Sheet.

BUSS-Loop® Reactor Technology

The heart of our gas-liquid reaction process designs is the technology we invented in the late 1940’s and that we have been improving on ever since.