ALKOXYLATION

JOIN THE BEST!

Buss ChemTech is recognised by the major manufacturers of alkoxylates as the world market leader in supplying alkoxylation technology. Our extensive experience in the realisation of commercial plants, based on the BCT-Loop Reactor technology, grants highest performance combined with an intrinsic safety.

Product Portfolio

Dedicated production technologies are available for virtually all Commodities and Specialities like:

- MPEGs

- Random and block EO/PO Co-polymers

- Bisphenol A alkoxylates

- Polyols

- Other PO derivatives or

- Any tailor-made product.

We have the solution ready. For brand new or unique products, our comprehensive R&D team with laboratories and pilot plants will optimize your process and you receive a cost-effective, tailor-made solution with product guarantees.

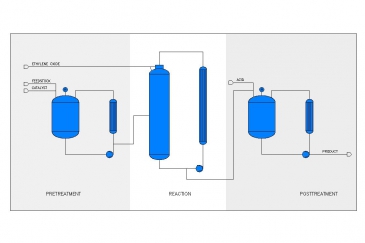

BCT layout principle

Depending on the complexity of your request, we offer you a one, two or even three pot system. The three pot system consists of:

- The Pre-Treatment section where catalyst and raw material are prepared and conditioned and the dehydration takes place.

- The Reaction section where the production takes place with growth rate up to 1:85 in one single run.

- The Post-treatment section where, if necessary, neutralisation, blending and bleaching is done.

Productivity / Efficiency

The BCT-Loop Reactor technology is characterised by

- very high ethylene oxide dosing rates (> 1000 kg/hr/m3)

- growth ratio up to 1:85 (starting volume : end volume) in one single shot

- short cook-down times

- high throughput

This results in remarkably reduced operational costs.

Safety Philosophy

Your safety is our MUST. Therefore our technology follows the Inherently Safe Design guidelines to eliminate potential risks during all production phases. There are intrinsic levels of safeguards such as:

- elimination of possible ignition sources (e.g. no rotating parts in the gas phase)

- inert conditions during all phases of the reactions

- deflagration-proof plant desig

Product Quality

Using the Buss Alkoxylation technology you reach a constant product quality without stripping

- EO content: Typically < 1 ppm in the product

- Dioxane content: Typically < 3 ppm in AEOs and < 10 ppm in NPEs

- Colour: Typically < 10 APHA in AEOs (1-9 EO) and 10.... 20 APHA in PEG and MPEG