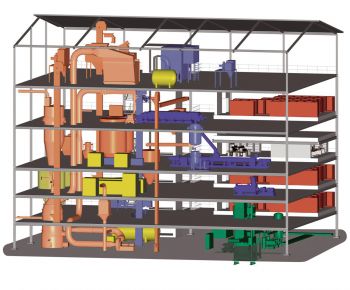

Green Anode Plant

BUSS ChemTech AG (BCT) offers the full scope of complete turnkey Green Anode Plants and upgrades to existing Green Anode Plants including technology enhancements. Our knowhow is based on 60+ years of experience in the aluminium industry focusing on dedicated anode production processes. We are a strong and reliable partner thanks to that experience and the many innovations we have made to the process over the years.